Making slow but steady progress on my poor Hula girl. As much as this sucks, I am enjoying learning to do some new maintenance procedures.

This is how my poor FJR has looked for quite some time now:

Removing the swing arm wasn't too bad at all. After 130k miles, it is a bit dirty.

The seal is yucky.

Swing arm pivot bearings seem fine. Ain't going to mess with them. New seals are on the way.

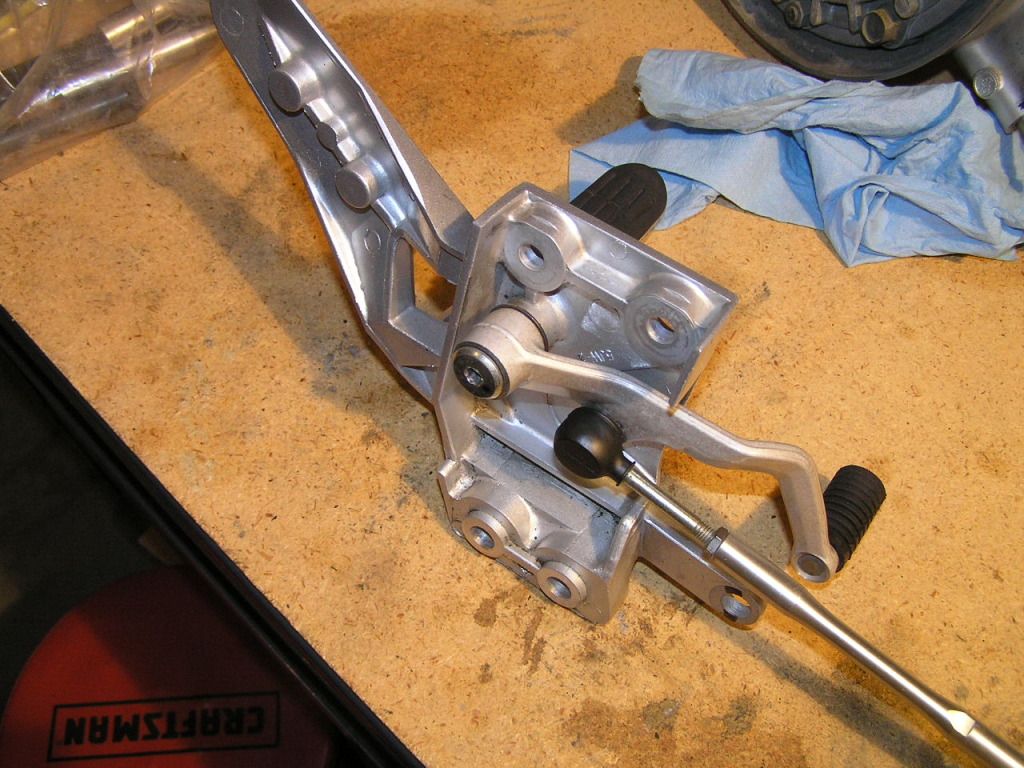

Bought a suspension relay arm from a 2003 FJR off ebay for $35 delivered. What a deal! I was hoping all the bearings would be good and I could just swap it in for the current one with the bad bearings.

But alas, even though the dogbones moved easily and smoothly, upon disassembly the center collar had the faintest of bearing marks on one side. I've learned my lesson and will get new bearings installed. The two single outer bearings on either end were fine.

So off to my favorite tech went the swing arm and new relay arm. There was no way I was going to attempt removing and pressing in new bearings. I just would have made things worse. Proper must-have tools here as far as I am concerned are a blind bearing puller, and a press.

While those pieces were gone, I did a lot of cleaning and serviced the final drive splines and U-joint. In just over 365k miles of FJR ownership I have never lubed my shift lever. Its never needed it as far as I am concerned. Well, since it had to come off to remove the swing arm, I lubed it. It's prettier now, but doesn't move any more smoothly. At least I

feel better. I guess.

Today I picked up the swing arm and relay arm with new bearings installed. Here's a photo of one of the new bearings in the relay arm. Puuurty.

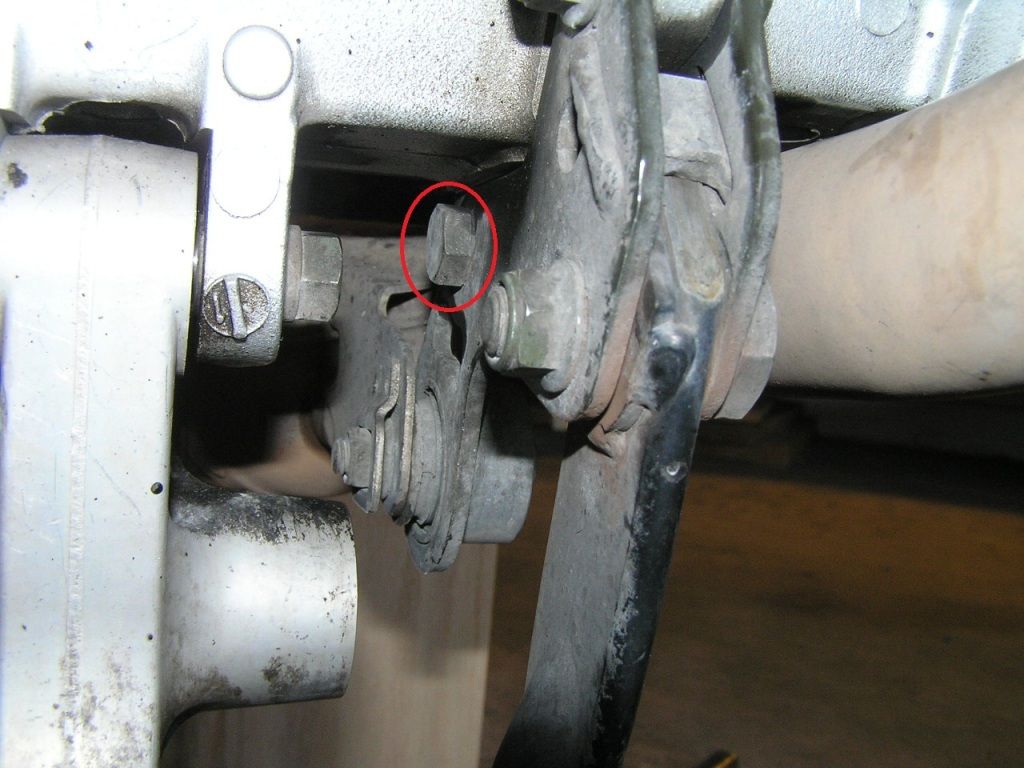

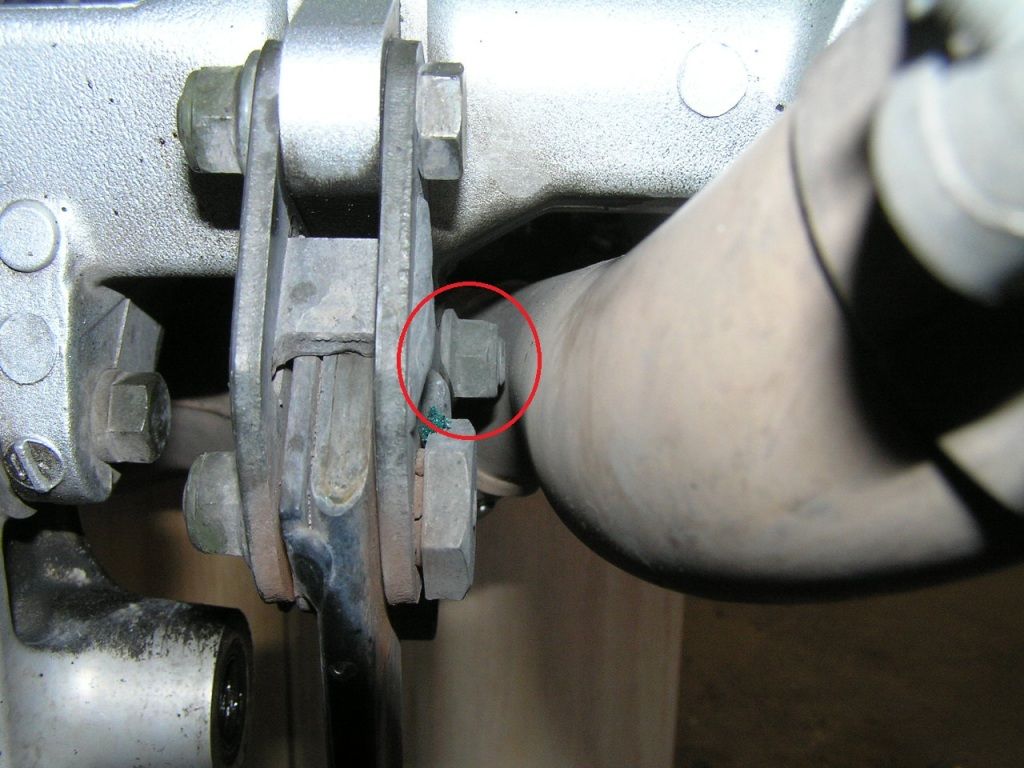

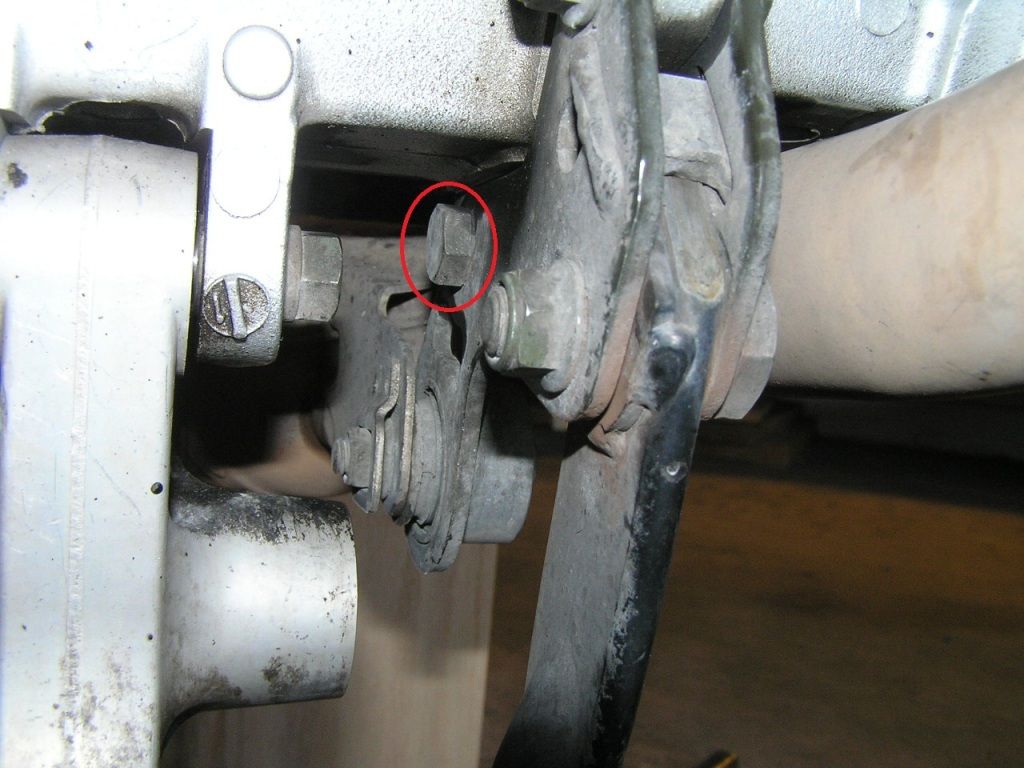

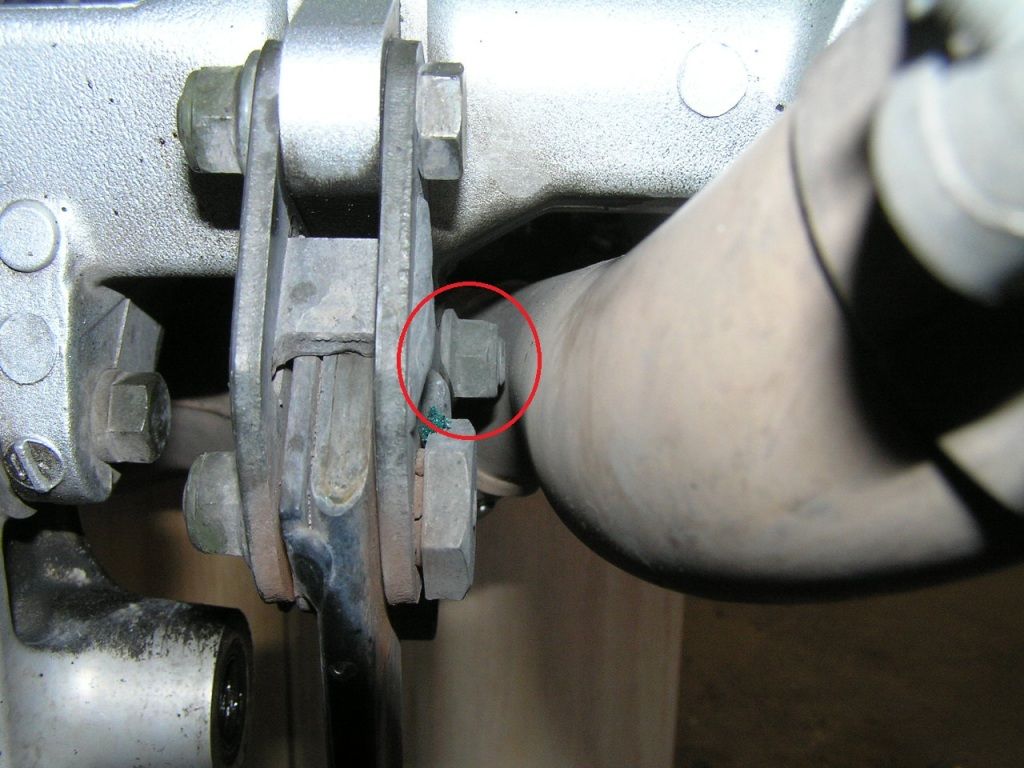

I then loosened all the C-stand bolts and upper relay arm bolt preparing for the big job once I have a way to suspend the FJR. These pieces are easy to get to with the swing arm removed. Lucky me, the PITA right side C-stand bolt had already been reversed. I bought the bike with 5900 miles on it. It did have an Ohlins shock on it when I bought it. They must have serviced everything and reversed that bolt when they installed the shock. Even with low miles. Lucky me! Photos of the usually offending bolt in the better orientation:

My newly serviced forks and Wilbers shock arrived from Traxxion this evening so everything is starting to come together. Tomorrow I will install the forks, a necessary step to keep the FJR stable while suspending the rear. Tomorrow I will also go and pick up a friend's home made hoist rack so I can suspend the rear and remove the C-stand. New seals for swing arm and relay arm are supposed to arrive Friday. I work Thursday through Sunday, so Monday will be a big day. Lube all the cleaned bearings, install new seals, remove C-stand, remove current relay arm and replace with ebay one with good bearings and then put everything back together. This has turned out to be one expensive maintenance evolution. At least the end of the tunnel is in sight.

Would like to say I am looking forward to a nice ride then, but I am way overdue for a valve check so that's next.

At 130k miles, Hula Girl is getting a new lease on life.